Underwater zero-buoyancy fiber optic cable, should be used in: underwater robots, underwater thrusters, underwater rescue robots, ROV, underwater detectors and other underwater equipment. It has the following features: good flexibility, acid and alkali resistance, corrosion resistance, light cable, strong tensile strength, etc., to ensure the normal use of equipment under the seabed

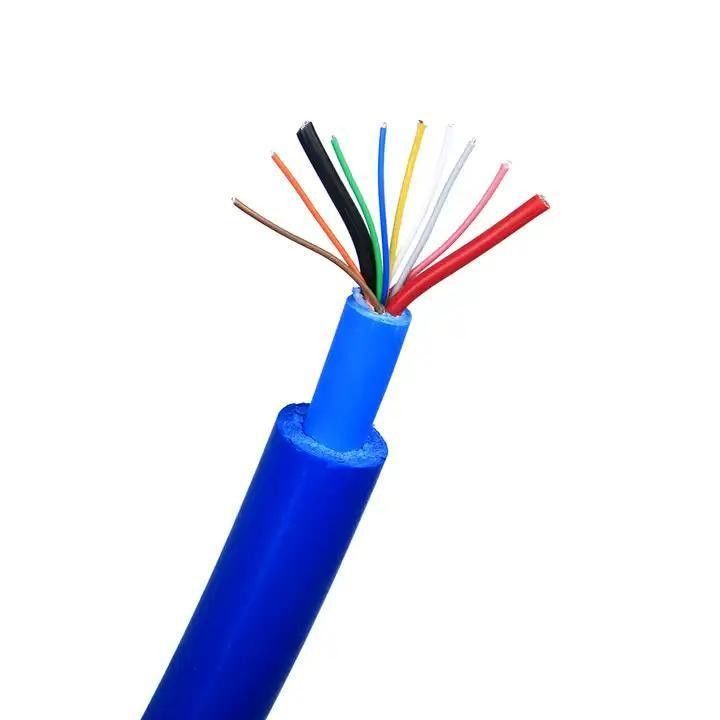

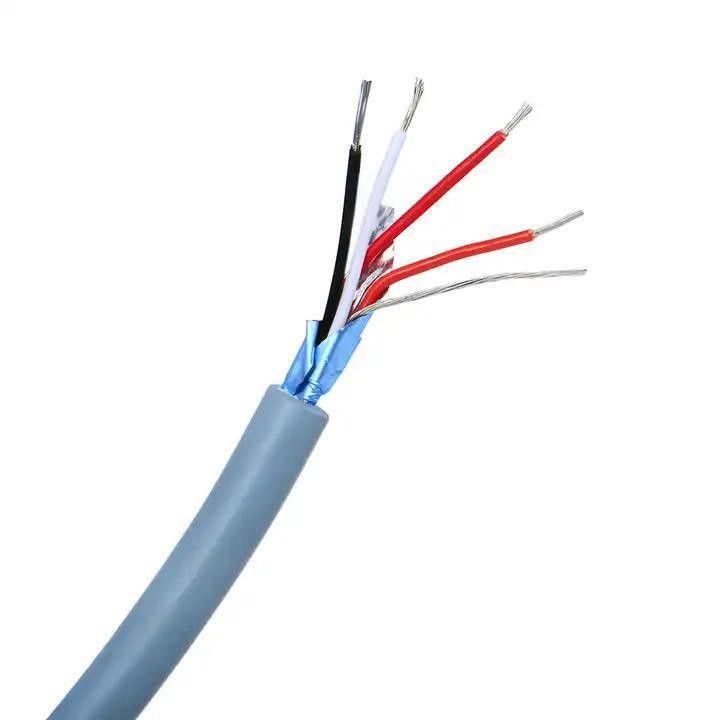

Conductor: Multi-strand ultra-fine oxygen-free bare copper wire/tinned copper wire finely twisted bundled cable conductor

Insulation: Foamed thermoplastic elastomer/TPV/TPE and other materials

Core wire structure: anti-twist structure design; grouped gap filling; twisted pair structure design

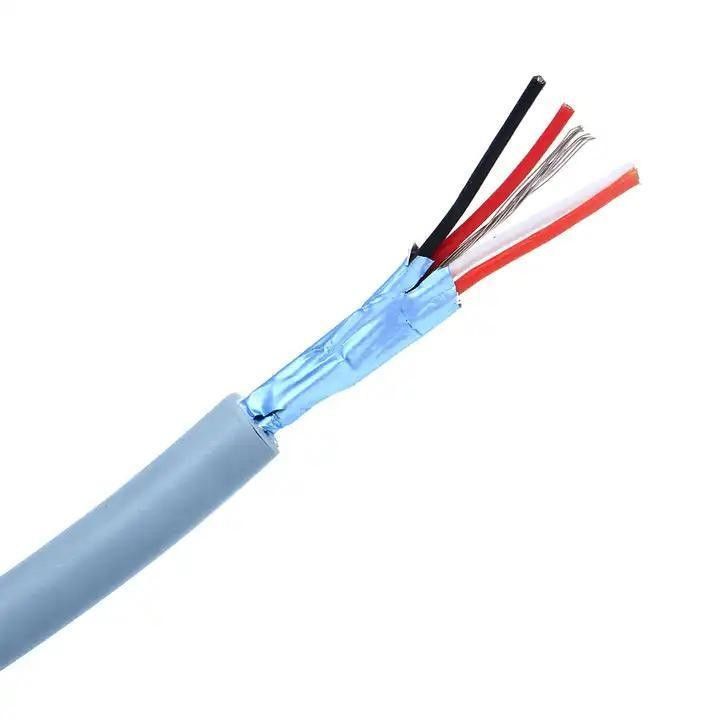

Shielding: Aluminum foil/tinned copper mesh; single or double layer sub-shielding + total shielding/total shielding structure design

Braided layer: Kevlar tensile fiber braided cable body

Sheath design: foamed polyurethane sheath design

Main Features

Flexible cable structure design, excellent folding and bending resistance

The cable buoyancy structure design avoids the excessive sinking of traditional cables due to their own weight, which brings burden to the underwater operation of equipment, and more effectively solves the problem of excessive sinking of traditional cables causing the connection between equipment.

Possibility of joint detachment

The cable uses Kevlar tensile fiber as the tensile load-bearing element of the cable (tensile filling or modified cable body). The cable has excellent tensile performance and the tensile strength of the cable can be customized according to specific needs;

The cable is used as a signal transmission and feedback cable. Aluminum foil Mylar and high-density tinned copper wire braid are used as the shielding material of the cable. Single-layer/double-layer shielding, as well as separate shielding + total shielding (single or double layer)/total shielding (single or double layer) can be designed according to needs. The cable has excellent anti-interference and anti-crosstalk performance, ensuring the stability of signal transmission feedback;

The outer sheath made of foamed polyurethane not only ensures the softness and buoyancy of the cable, but also has excellent properties such as waterproofness, oil corrosion resistance, and hydrolysis resistance. It has strong environmental adaptability and can be used not only in freshwater environments, but also in seawater environments and highly polluted water environments.

Main parameters of the product

Rated voltage: core wire <0.5mm2, 300/300V; core wire ≥0.5mm2, 300/500V

Test voltage: 2000V

Temperature range: -30~+80℃

Mobile bending installation radius: 7.5*D (cable outer diameter)

Products

![]()

![]()